Buying notice:

1.When we delivery, we usually use other products name to write on parcel, so can avoid high certificate costs for air transport, hope can understand this.

2. For lower prices or bulk prices, welcome email to us make further negotiation. We will check whether have cheaper freight costs to your address.

Other name: Molybdenum silicide

Molecular formula: MoSi2

CAS number: 12136-78-6

Molecular weight: 152.11

Melting point: 2030 ° C

Density: 6.24g/cm3

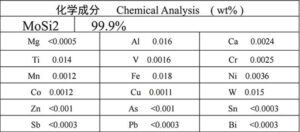

Purity: 99.9%

Particle size: 1—3um

Appearance: Gray-black powder

Crystal form: Quartet

Thermal conductivity: 45W / m.K

Thermal expansion coefficient: 8.1 × 10 -6 K-1

Resistivity: 21.5 × 10 -6 Ω.cm

Vickers hardness (HV): 10.6Gpa

1. Basic characteristics of molybdenum disilicide powder:

Molybdenum disilicide (MoSi _ 2) not only has the high melting point, corrosion resistance and oxidation resistance of ceramics, but also has the electrical conductivity and high-temperature plasticity of metallic materials, and also has a low specific gravity. MoSi _ 2 is an intermediate phase with the highest silicon content in binary alloy system, and has the dual characteristics of metal and ceramics. Molybdenum disilicide ceramic powder produced by Yinuo materials has high purity, narrow particle size distribution, good high-temperature oxidation resistance, high-temperature plasticity, thermal conductivity and fluidity, and is widely used in the field of high-temperature structural ceramics.

2. Main uses of molybdenum disilicide powder:

1) It is used for heating elements, integrated circuits, high-temperature oxidation-resistant coatings and high-temperature structural materials, and its main purpose is to make heating elements working in an oxidizing atmosphere;

2) Used in glass kilns as fused glass electrodes, bubbling tubes, thermocouple protection tubes, gas sampling tubes, etc.

3) Used for thick modulus resistance, conductive oxidation-resistant coating, integrated circuit film, etc.

4) Gradient high-temperature oxidation-resistant coating for molybdenum disilicide-based composite materials, such as high-temperature structural parts and refractory metals;

5) used as matrix phase of structural composite materials and reinforcing agent of other structural ceramics;

6) Used for producing ceramic products, sputtering targets, etc..

Reviews

There are no reviews yet.