Under the action of an external excitation source, the phenomenon that a substance or a system has a significant change in color is called chromatism. Discoloration can be observed in gases, liquids or solids. External excitation sources can be light, heat, electricity and pressure.

Let’s start with photochromic materials. Photochromism refers to the phenomenon that when A compound A is irradiated by a certain wavelength of light, A photochemical reaction can occur to obtain a product B, and the color of A and B (that is, the absorption of light) is significantly different. B can be restored to its original form A under the irradiation of another beam of light or by heating. The most familiar is the silver halide system commonly used in photosensitive photography, in which silver microcrystals dispersed in glass or film become black under ultraviolet light, but reverse when heated in the dark and become colorless. Another important application of this system is as color-changing sunglasses that automatically adjust the intensity of transmitted light.

A CD with a photochromic polymer as its recording layer is a scrubable and reusable CD because photochromism is a reversible reaction in which a laser matching the absorption wavelength of the starting compound A is used to record an image or graphic information, and a microdot of the photochemical product B is obtained in the laser spot irradiation region. After the disc is recorded, if you want to modify or do not need the original information, you can use heating or laser processing with the photochemical product B, so that the original micro points will disappear and become blank. Compared with traditional optical discs, photochromic optical discs have many advantages, such as high storage density, fast optical response, good anti-magnetic and anti-fouling performance, easy processing and low cost.

Thermochromism refers to the color changes that occur when some compounds or mixtures are heated or cooled. At present, thermochromism materials have been widely used in aerospace, petrochemical, machinery, energy utilization, chemical anti-counterfeiting, daily decoration and scientific research. The use of special occasions is incomparable to other methods. One of the simplest examples in middle school chemistry is the discoloration of the NO2 molecule, where temperature causes the chemical equilibrium to shift and the color to shift between reddish-brown (NO2) and colorless (N2O4). In fact, the precious ruby is also a typical hot color material.

Electrochromism refers to the phenomenon that the optical properties of a material produce stable reversible changes under the action of an applied electric field, and the appearance properties are manifested as reversible changes in color and transparency. In recent years, a variety of electrochromic devices have been developed, mainly information display devices, electrochromic smart Windows, non-glare mirrors, etc., in addition to high resolution photoelectric camera equipment, photoelectric chemical energy conversion and storage, electron beam metal plate printing technology and other high-tech products, the prospect is very attractive.

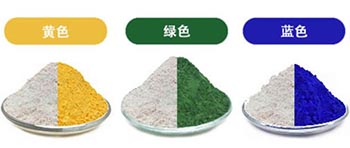

Piezochromism, which changes color with pressure, has been found in some materials, but there are few theoretical studies. In the application research, the structure research and application of various hues of pressure sensitive pigments have achieved a lot of results. Recently, the United States applied a pressure-sensitive coating to determine the pressure of various parts of the wings of aircraft in flight. In the past, a “load model” has to be built in aircraft design, which is costly and time-consuming, and the obtained data can not fully reflect the surface pressure distribution. The color compression material is applied to the surface of the wing, and the pressure of each part can be reflected conveniently and comprehensively according to the color changes of each part in the experiment. In particular, it is impossible for the “load model” to complete the pressure test on some extremely thin surfaces of the wing with piezochromatic materials. In addition, the use of pressure sensitive dyes in the sealing of food plastic packaging can effectively check the sealing of the packaging bag to ensure the quality of food.