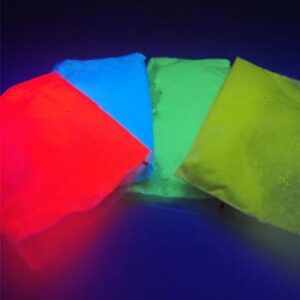

Main characteristics

High infrared reflectivity (cold pigments)

Easily dispersed

Good dimensional stability, no color infiltration, no migration

Excellent weather resistance

The chemical structure of the pigment is stable

Excellent temperature resistance

Application guide

Suitable for the total solar reflectance (T.S.R) requirements of the coloring system;

Suitable for the detection of black plastic packaging recycling;

Suitable for PVC-P; PVC-U; PUR; LD-PE; HD-PE; PP; PS; SB; SAN; ABS/ASA; PMMA; PC; PA; PETP; CA/CAB; UP and other polymers; Color master batch; Engineering plastics; Wood plastic; Powder coating; Water-based paint; Solvent-based coatings; High temperature baking coating; Coil coating; Fluorocarbon coatings; Automotive coatings; Camouflage paint; Printing ink; Building materials; Cement; Mortar; Concrete; The roof; Sintered colored sand.

On buildings, the roof is the main part of solar radiation to absorb heat. The radiation falling on the roof is either reflected into the atmosphere or absorbed into the building by conduction. Any absorbed solar radiation will heat the roof surface and some heat will enter the building. The higher the absorption of solar radiation, the higher the energy consumption, keeping the building cool; Mainly by air conditioning, which is widely used in large buildings. By lowering the temperature of the building surface and reducing the heat entering the building, air conditioning can save energy. By protecting the external surface of the building from the heat radiated by the sun, the external surface temperature can be reduced. Several technologies to prevent solar radiation have been put forward, among which the use of cold pigments has aroused great interest in the past few years. Cold pigments refer to pigments with high near-infrared (NIR) solar reflectivity or low near-infrared solar absorptivity, which are widely used for coating or coloring sintered colored sand on roofs and external walls of buildings.

Reviews

There are no reviews yet.